PCV diaphragm failure is a classic engine problem, but thankfully, it’s one with a straightforward fix. Think of the diaphragm as a hard-working part that’s constantly dealing with engine vacuum, high heat, and oil vapor. Over time, it just gets tired and wears out. When that diaphragm gives up, your engine’s crankcase pressure goes haywire, leading to oil leaks, a shaky idle, and other performance hiccups.

The good news is the problem is usually just the diaphragm itself. A PCV diaphragm repair kit is made for this exact situation, letting you fix the issue without having to buy a whole new PCV assembly or valve cover.

Key Takeaways

Critical Function: The PCV diaphragm regulates crankcase pressure by venting gases back to the intake; failure disrupts this balance, causing vacuum leaks and performance issues.

Distinct Symptoms: Signs of a torn diaphragm include a loud whistling or squealing noise, rough idle, oil leaks, and “system too lean” engine codes (e.g., P0171).

Targeted Solution: Repair kits provide a cost-effective alternative to replacing the entire valve cover assembly by supplying only the necessary components (diaphragm, spring, and cap).

Material Upgrade: High-quality aftermarket kits often use FKM (Viton) instead of standard rubber, significantly increasing heat resistance and part longevity.

Straightforward Repair: PCV diaphragm replacement is a manageable DIY task taking 30–60 minutes, provided the housing is thoroughly cleaned to ensure a proper seal.

Table of Contents

Role of the PCV Diaphragm in Engine Operation

So, what does this little rubber disc actually do? The PCV diaphragm is the gatekeeper for crankcase gases. As your engine runs, some combustion gases sneak past the piston rings and build up pressure in the crankcase. The diaphragm’s job is to safely vent these gases back into the intake manifold to be burned off.

It works by balancing the vacuum from the intake. At idle, when the vacuum is strong, the diaphragm only opens a little to prevent too much suction, which could pull oil into the intake. When you accelerate and the intake vacuum drops, the diaphragm opens wider to allow more gases to escape. This keeps the pressure inside your crankcase perfectly managed.

Essentially, it’s a smart valve that protects your engine by keeping oil where it belongs and ensuring your air-fuel mixture stays stable. When it tears, that delicate balance is lost, causing immediate and noticeable problems. This issue is especially common in certain engines, like Volkswagen’s 2.5L and BMW’s B58, where the diaphragm is a known failure point.

Signs of a Damaged PCV Diaphragm

When a PCV diaphragm fails, it doesn’t whisper, it shouts. The symptoms are physical and consistent, not like those tricky electronic gremlins. If you’re experiencing any of these, there’s a good chance your diaphragm is the culprit.

- A Loud Whistling or Squeal: This is the most common giveaway. Air getting sucked through the torn diaphragm often creates a high-pitched noise that sounds like a tea kettle at idle.

- Rough Idle and Misfires: The tear creates a vacuum leak, throwing off the air-fuel mixture. This can make your engine idle erratically, misfire, or even stall out completely.

- New Oil Leaks: When the diaphragm can’t vent pressure, it builds up inside the crankcase and forces oil out through the weakest points, like valve cover gaskets and crankshaft seals.

- Increased Oil Consumption: A strong, unregulated vacuum can suck oil mist directly into the intake manifold, causing your engine to burn oil.

Your check engine light will likely pop on, too. When you scan it with an OBD-II reader, you might see codes like P0171 (System Too Lean) or P052E (Positive Crankcase Ventilation Regulator Valve Performance), which point directly to a PCV system problem.

What Comes in a PCV Diaphragm Repair Kit

A good PCV diaphragm repair kit gives you exactly what you need to replace the failed parts without any extra fluff. A typical kit from a reputable brand like Dorman or Klifex will include a few key items.

- A new diaphragm: This is the star of the show, usually made from a high-quality, oil- and heat-resistant material.

- A retaining cap: The original plastic cap can become brittle and break during removal, so a new one is often included.

- A new spring and seals: These ensure the new diaphragm operates correctly and seals tightly.

Pro Tip: Many quality aftermarket diaphragms are made from FKM (often known by the brand name Viton), which can withstand temperatures up to 400°F (about 204°C). This is a significant upgrade over the standard NBR rubber used in many original parts, which often fails at around 250°F (121°C). This material upgrade is a key reason why a repair kit can be a more durable solution.

PCV Diaphragm Replacement Process

Replacing the diaphragm is a job most DIYers can handle in about 30 to 60 minutes with basic tools. First, you’ll need to confirm the failure. You can often hear the whistling sound or use a smoke tester to find the vacuum leak.

Once you’ve pinpointed the problem, you’ll remove any engine covers to get to the PCV housing, which is usually part of the valve cover. Be gentle when prying off the old cap, as the plastic tabs can be fragile. A set of plastic trim removal tools works perfectly here.

After you pop the cap off, pull out the old, torn diaphragm and the spring. Now for the most critical step: cleaning. Thoroughly clean out any oil sludge or residue from inside the housing. Any leftover gunk can prevent the new diaphragm from sealing properly, causing the fix to fail.

Finally, place the new diaphragm and spring correctly, ensuring the edge of the diaphragm sits perfectly flat in its groove. Snap the new retaining cap firmly into place until it clicks. Reassemble everything, start the engine, and listen. A smooth, stable idle with no whistling means you’ve successfully fixed the problem.

Benefits of Using a PCV Diaphragm Repair Kit

Opting for a repair kit isn’t just about fixing the problem; it’s about making a smart, cost-effective choice. Instead of replacing a perfectly good valve cover, you’re targeting only the component that failed.

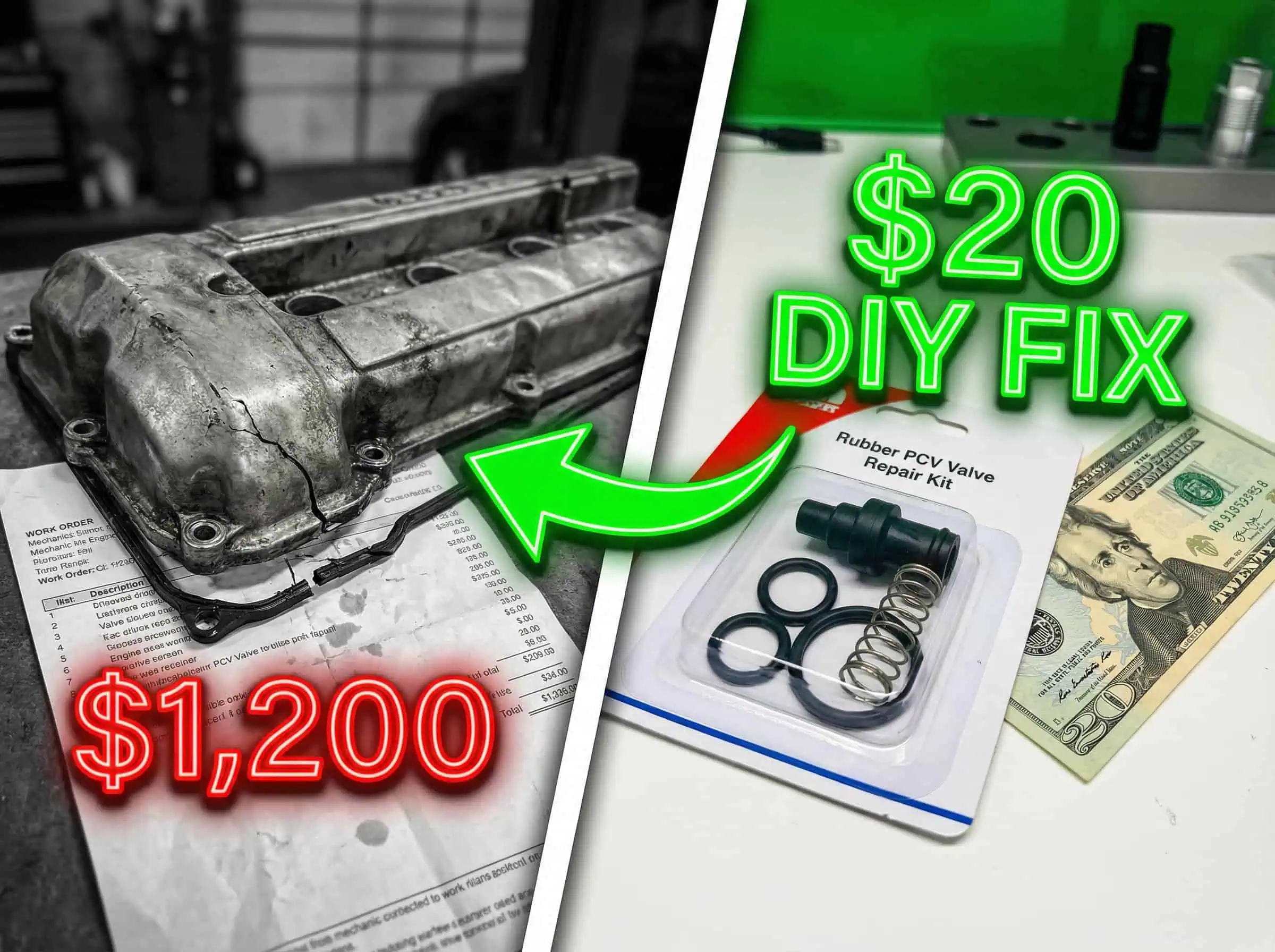

The cost savings are the most obvious benefit. A full valve cover assembly replacement can be expensive, with dealership quotes sometimes running over $1,000 for parts and labor. In contrast, a high-quality PCV diaphragm repair kit typically costs between $20 and $50. That’s a huge difference.

Beyond the savings, you also get a more durable part. As mentioned, many aftermarket kits use superior materials like FKM that outlast the original factory components. Restoring proper crankcase pressure also prevents serious downstream damage to expensive parts like engine seals and catalytic converters.

In short, a PCV diaphragm failure is a precise mechanical issue with a precise solution. Using a well-engineered repair kit is the most efficient, reliable, and technically sound way to get your engine running smoothly again.